Periodic Inventory System

Introduction to Periodic Inventory System

For many businesses, the ability to manage and monitor inventory efficiently can significantly impact profitability and operations. One of the traditional methods employed for this purpose is the “Periodic Inventory System.” Unlike real-time inventory management systems, this method involves counting inventory at predetermined intervals, typically aligning with the end of a financial period.

Core Mechanism of the Periodic Inventory System

Physical Counts at Set Intervals

The central tenet of the periodic inventory system is that physical counts of inventory are conducted at set intervals. These intervals can range from monthly and quarterly to annually, depending on the business’s needs and the nature of its products.

Adjustment Based on Physical Count

After each physical count, the recorded inventory levels are adjusted to match the actual quantities counted. This adjustment ensures the accounting records align with the real inventory on hand.

Advantages of the Periodic Inventory System

Simplicity and Lower Costs

For businesses that cannot invest in advanced inventory management software, the periodic system provides a simpler, more cost-effective alternative.

Suitable for Smaller Inventories

Businesses with a limited range of products or smaller inventory quantities might find the periodic system more manageable and efficient.

Lower Dependency on Technology

The periodic system does not necessarily require sophisticated technological infrastructure, making it less prone to technical glitches.

Potential Challenges and Solutions

Potential for Errors

Physical counts can lead to discrepancies due to human error or items being overlooked.

Solution: Employing multiple counters and using standardized counting procedures can help minimize errors.

Stockouts

Without real-time updates, there’s a higher risk of running out of stock, leading to lost sales opportunities.

Solution: Regular monitoring of fast-moving items and keeping a buffer stock can help mitigate this challenge.

Time-Consuming

Physical counts, especially for businesses with larger inventories, can be time-consuming.

Solution: Efficient organization, using barcode scanners, and segmenting the inventory can expedite the counting process.

Periodic vs. Perpetual Inventory System

The periodic inventory system stands in contrast to the perpetual inventory system, where updates are continuous and in real-time.

Key Differences:

- Update Frequency: Set intervals in the periodic system; continuous in the perpetual system.

- Technological Infrastructure: The periodic system typically requires less advanced technology than its perpetual counterpart.

- Accuracy and Labor Intensity: Physical counts in the periodic system can be labor-intensive and may lead to discrepancies, while the perpetual system offers higher accuracy with reduced manual intervention.

Implementing a Periodic Inventory System

Businesses considering the periodic inventory system should:

- Determine Suitable Intervals: Based on product turnover rates, decide on the most optimal frequency for physical counts.

- Standardize Counting Procedures: Ensure consistency in counting methods to minimize errors.

- Review and Adjust: Post-count, promptly adjust the records, and address discrepancies, ensuring alignment with actual stock.

Disclaimer: This article offers a foundational understanding of the periodic inventory system. It is meant for informational purposes and does not constitute financial or legal advice. For detailed insights, businesses should consult professionals.

Contact Us

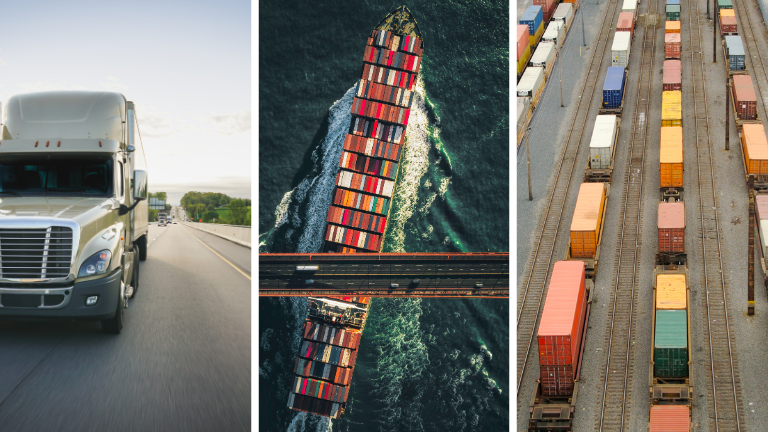

The world of logistics is complex and full of technical, financial, and business elements. The logistics experts at Phoenix International deliver top-quality freight forwarding service, supported by powerful technology and decades of experience. Contact us and let us know how we can help you!